Preventive Maintenance and Repairs

We help our clients meet their facility’s needs by repairing and maintaining all types of chillers and maintaining all types of chillers may it be Centrifugal, Screw, Absorption, etc. We also repair other HVAC equipment which includes Cooling Tower, Air Handling Unit, Fan coil unit (FCU), Packaged Air-conditioning Unit (PACU), pumps, unitary units, etc.

Operatorship and Maintenance Assessment

We offer operatorship & maintenance for electromechanical equipment’s such as chillers, cooling tower, heat exchanger, pumps, air compressors, refrigeration equipment, etc. Through our experienced operators, we optimize the performance of an existing facility.

Water Treatment

Services

We offer water treatment services which primarily include descaling, tube cleaning, etc. Our treatment program shall be backed up by competent technical engineers, service technicians and chemical analysts equipped with the latest technology.

Equipment and

Parts Sales

We can supply your every facility’s needs from the equipment to its smallest parts and this includes:

Chillers

Cooling Towers

Air Handling Units

Fan Coil Units

VRF Systems

Unitary Units

Packaged Air-Conditioning Unit (PACUs)

Pumps

Technical Manpower

Supply

We supply manpower to different sites to assist them in technical, mechanical and building maintenance management.

CHILLERS

OIL-FREE MAGNETIC BEARING CHILLERS

SMARDT remains the global trusted leader in high efficiency oil-free cooling, since it delivered the world’s first oil-free chillers in 2002. SMARDT oil-free centrifugal chillers offer the highest efficiency, lowest maintenance cost, and optimum reliability. Designed for a 30-year operating life, with only one major moving part. Available in water cooled and air cooled configuration.

Water Cooled Centrifugal Chillers

Capacity: 60 TR- 2500 TR; Refrigerant : HFC-134A

Air Cooled Centrifugal Chillers

Capacity: 60 TR-440 TR; Refrigerant :HFC-134A

CHILLERS

CENTRIFUGAL CHILLER

• Inverter direct-drive full falling film centrifugal chiller

• Magnetic full falling film centrifugal chiller

• High-efficiency water cooled centrifugal chiller

• Super high efficiency water cooled centrifugal chiller

WATER COOLED SCREW CHILLER

• Full falling film type

• Flooded type

AIR COOLED SCREW CHILLER

• Inverter air cooled screw chiller

• Capacity from 556 to 1330 KW

COOLING TOWERS

Cooling Tower Institute (CTI) – certified cooling towers are available in cross flow and counter flow configurations using advanced thermal exchange technology, marked by high efficiency, low noise, low drift loss, and stable operation. The factory boasts of a modern cooling tower testing center employing tests on thermal performance, operating noise, fan performance and other relevant testing procedures.

Capacity: 150 – 1650 TR

COUNTER FLOW SQUARE TYPE

CROSS FLOW SQUARE TYPE

COUNTER FLOW ROUND TYPE

AIR HANDLING UNITS

KINGAIR’s patented double framing Air Handling Unit is an innovative product especially designed for durability and reliability. All metals elements in the cabinet are isolated by PU foaming and a rubber rib seal designed to eliminate thermal bridging. The double wall structure is insulated by high density polyurethane foam fastened by bolts and nuts,with rubber seals resulting in a leak-tighten closure. Internal and external steel framing provide rigidity and strength to the entire structure of the unit.

Standard design is using Double-Wall Insulated Casing. Double-wall insulated casing can be of different thickness(1“,2“,3“,4“),insulated with different insulation materials (polyurethane, fibre-glass, rockwool) and internally lined with plain or perforated sheet; selected to meet any fire protection requirement, thermal insulation requirement, acoustic attenuation, noise-breakout requirement and specific environmental requirement.

FAN COIL UNITS

BRUSHLESS DIRECT CURRENT (BLDC) FCU

KINGAIR fan coil unit applied the latest technology of permanent magnet brush less direct current motor which can proceed continuous and steeples capacity control. Power consumption at low speed operation is 75% lower than National Standard. Low noise, high efficiency, energy saving with isothermal control, it is your best choice of highly energy saving Fan Coil Unit.

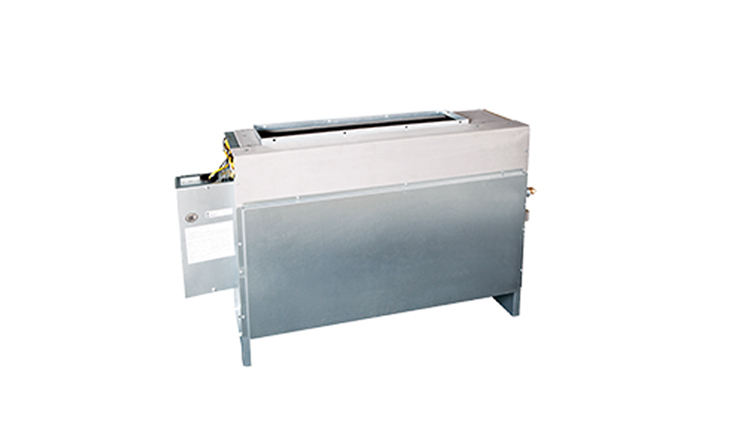

CHILLED WATER LOW STATIC DUCTED UNITS (SCLF SERIES)

• Capacity range: 200 ~ 2000 CFM.

• Wide external static pressure supplying. Three external static pressure(12Pa/30Pa/50Pa) settings for added flexibility.

• Standard extended drainage pan for protecting your ceiling better.

• Left or right hand piping connections, field convertible.

• Flexible control, remote controller and wired controller are optional.

• A patent design is able to prevent abnormal noise caused by blowing fins.

• Higher efficient heat exchange for complete contranatant flow.

• Return air plenum and filter are standard.

• Fresh air supply makes life healthier and more comfortable.

• 220-240V/1Ph/50Hz power supply is standard.

VARIABLE REFRIGERANT FLOW (VRF) SYSTEMS

Also known as Variable Refrigerant Volume. It is an advanced method of air conditioning. The flow of Hisense VRF refrigerant can be varied according to the cooling and heating needs. The room temperature can be kept in a special range, which improved the comfort level of the indoor environment. This type of system consists a number of indoor units. One outdoor unit can connect one or more indoor units. The overall refrigerant flow depends on how many indoor units is working. The intelligence control system of Hisense VRF enables switching between the heating and cooling modes.

KEY FEATURES AND BENEFITS

• Advanced technology

• High quality and high efficiency

• Intelligent control system

• Energy Savings

A. INDOOR UNITS

Ceiling Ducted Type

Ceiling Ducted Type (Low height)

4-way Cassette Type

2-way Cassette Type

1-way Cassette Type

Ceiling and Floor Type

Wall-mounted type

Floor-concealed type

Console

B. OUTDOOR UNITS

- TOP FLOW -

Hi-FLEXi S Series

Hi-FLEXi G + Series

Hi-FLEXi X Series

Hi-FLEXi R Series

Hi-FLEXi W Series

- SIDE FLOW -

(02) 809-3916

(02) 809-3916 GET IN TOUCH

GET IN TOUCH